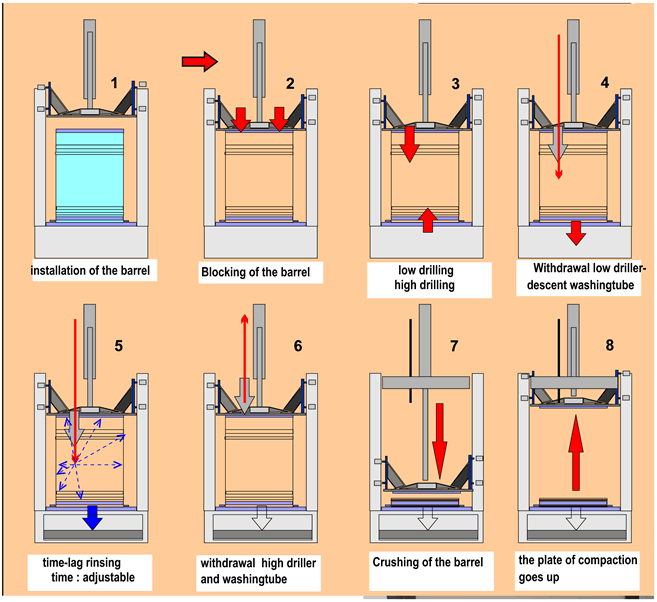

With automatic rinsing device

rinsing of barrels, compression, depollution

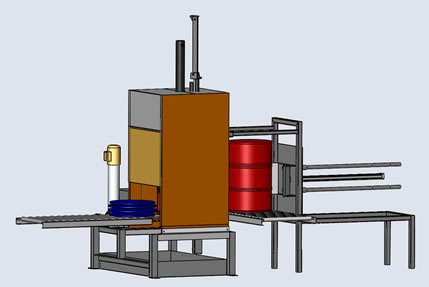

rinsing of barrels, compression, depollution  overall picture

overall picture

General characteristics of the components |

|

|---|---|

| Pressure of compaction (tons) | 18 tons / 29 tons |

| hydraulic power for compaction and drilling | 7,5 kW |

| Multicellular pump with flushing water 3-10 bars | 4 kW |

| Cane washing with hydraulic descent | |

| Rotary tube of washing PVFD or stainless | 360° |

| Hydraulic tool for drilling of the lid 80x60mm | stroke 250 mm |

| Hydraulic tool for drilling of the bottom 50x90mm | stroke 200 mm |

| Total electric power | 12 kw / 400V / 50 Hz |

| Vat of retention with valve | 300 liters |

| Adjustment of the time of rinsing | 0 à 60 sec |

| Possibility of crushing without rinsing | option ATEX possible |

| High limit of size of the barrels (diameter X height) | 650x910 mm / 650x1092 mm |

Cane washing with auto-revolving rotary tube |

|

| Water consumption, in liters for 20 seconds of rinsing, according to the pressure |

||||

|---|---|---|---|---|

| Type oftube | Type of the jet | Pressure of use (bar) Maximum 10 bars |

||

| 3 | 5 | 10 | ||

| 360° - PL | 4,5 | 6,3 | 8 | 11,3 |

| 360° - PL | 9,9 | 13,3 | 17,3 | 24,3 |

| 360° - PL | 13,6 | 18,3 | 23,6 | 33,6 |

| values for auto-revolving rotary tube.----PL: smooth bearings. | ||||