French design and manufacture

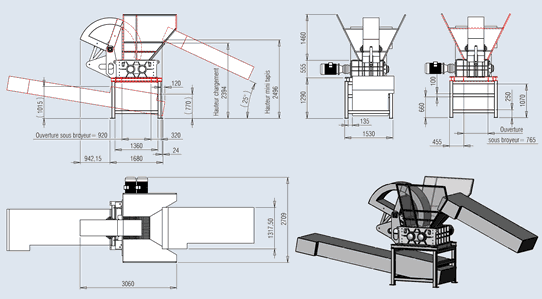

B 840-750-44kw

Equipped with a power of 44 kw,

of a cutting width of 750 mm,

it adapts to the most difficult cases

| Name | B840/750 | B840/1000 | B840/1250 |

|---|---|---|---|

| Size of cutting block mm | 758 x 840 m | 1008 x 840 mm | 1250 x840 mm |

| Number of shafts | 2 | 2 | 2 |

| Width of blades | 500/540 mm | 500/540 mm | 500/540 mm |

| Number of blades thickness 40 mm | 19 | 25 | 32 |

| Number of blades thickness 50 mm | 15 | 20 | 25 |

| Width of shafts | 150 mm | 150 mm | 150 mm |

| Rated rotation speed | 10/21 tpm | 10/21 tpm | 10/21 tpm |

| KW | 30-44 kW | 30-44 kW | 30-44 kW |

| Power | 400 V | 400 V | 400 V |

| Protection fuse | 63-120 A | 63-120 A | 63-120 A |

| Approx. weight | 3300 kg | 3700 kg | 4200 kg |

| Electronic control: automatic reverse-start-stop overload | |||

| French design and manufacture - “CE” certified - 1 year guarantee(*) – Subject to technical and optical modifications | |||

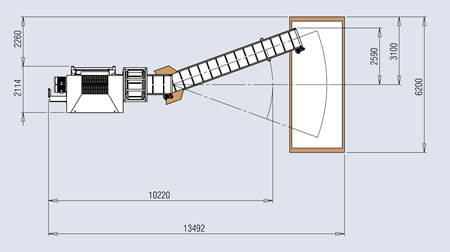

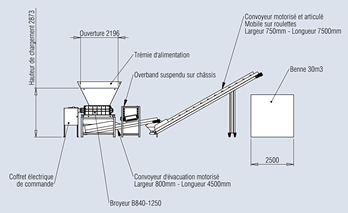

Crushing and sorting of computer material: Feeding conveyor, Broyeur B840, magnetic sorting with overband, emptying conveyor

| TEST GRINDING: .........NATURE ....... WASTE: .......... PC, Computer CPU | ||

|---|---|---|

| MACHINE | ....B840/1750/30CS | Config: ........................knives |

| quantity: ...............................2 | Weight: ........................................kg 18,7 | Duration in sec: ............................115 |

| kg/hour: ..........................585 | Vol/hourt: ..................................3,5 M3 | |

| Volume before: ..................0,11m3 | Volume after:..........................0,041 m3 | |

| Density before: ..................0,167 | Density after: .............................0.460 | Reduction volume: .......................2,752 |

| COMMENT | coarse grinding for metal separation by Overband and manual sorting of non-ferrous | |

| TEST GRINDING:.......... NATURE ....... WASTE: .......... PRINTERS MACHINE | ||

|---|---|---|

| MACHINE | ....B840/1750/30CS | Config: ........................Knives |

| quantity: ...............................2 | weight: ........................................kg 22,2 | Duration in sec: ............................255 |

| kg/hour: ..........................313 | Vol/hour: ..................................3,5 M3 | |

| COMMENT | coarse grinding for metal separation by Overband and manual sorting of non-ferrous | |

Crushing of parts of automobile body B840-1250